LASER WELDING FOR TOOL AND DIE, MEDICINE AND SENSOR TECHNOLOGY

We use the pulsed laser welding and CW laser welding processes.

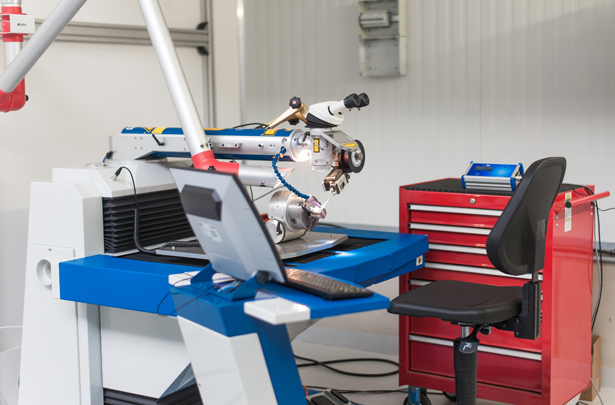

In laser welding, L & A Lasertechnik und Applikationen GmbH is one of the leading companies in Saxony and beyond. The experienced team, the excellent technical equipment and the rich wealth of experience from more than 20 years are our company’s quality guarantee.

Using laser welding to join components has many advantages over other welding technologies. The final products stand out for their narrow weld seams and high strength, among other things. Moreover, the technology can also easily handle demanding tasks like joining metals with different melt points.

In addition to welding at our premises, we also offer mobile laser weldingwith the ALPHA LASER ALM 250. If a component is too large or heavy to transport, we’ll do the work at your site.

As the sales and service partner of ALPHA LASER GmbH for eastern Germany, we’re competent contacts for all questions related to laser application technology. We know what can be done — and we’ll openly tell you what can’t.

In addition to laser welding, our portfolio includes many other services. Laser engraving and laser inscription of a wide range of materials open new design and marking options completely without mechanical stress on the component. Both technologies provide highly precise results, and are also economical and environmentally friendly.

Customers from a wide variety of industries also value our expertise in arc welding technologies (TIG, MIG/MAG welding). They come into play, among other things, when welding thin sheets of aluminum and stainless steel (TIG welding) and when producing or repairing heavy steel constructions (MIG/MAG welding). During our obligatory consultation, we specify the optimal welding technology for the purpose at hand.

Moreover, we also take on individual orders that go beyond the norm. Our production hall in Boxdorf, near Dresden, is a point of contact for anyone who needs occasional support — such as goldsmiths or other artisans, but also private customers with repair jobs, or car lovers who want to have welding done as they restore a classic car.

Frequently asked questions and answers.

Which laser welding processes do you use?

We offer pulsed laser welding and CW laser welding. More information can be found in the “Laser Welding” section.

What machines do we use to process your orders?

For laser welding, we use lamp-pumped Nd:YAG lasers (300 W) and fiber lasers (600 W or 900 W) from ALPHA LASER.

In arc welding, we work with TIG and MIG/MAG welding equipment from REHM Schweißtechnik.

For 2D inscribing and 3D engraving, we use a FOBA lamp-pumped Nd:YAG laser engraving system.

What materials can we weld for you?

We weld tool steels, stainless steels, low-alloy steels, aluminum alloys, multi-material bronzes, Ampco and Ampcoloy alloys, magnesium alloys, titanium, tantalum, platinum-rhodium alloys, gold, silver, copper, nickel alloys, steel and gray cast iron alloys.

Which differing pairs of materials can be welded?

Among others, we have done black-and-white joints (low-alloy steel with stainless steel) and copper-stainless steel joints. With deposit welding, it is possible to create functional areas on low-alloy or tool steels with certain multi-material bronzes.

Can cast iron be welded?

There’s no one answer to that. In such cases, we decide on weldability based on the variety of alloy types and qualities, the age of the component and its functionality after thorough incoming inspection and a test weld. Most components of the materials mentioned are good for joint and deposit welding Which welding process (laser, TIG, MIG/MAG) is used is evaluated and specified individually. Contact us — we’ll be happy to advise you!

Can cast steel or cast aluminum be welded?

Most components of the materials mentioned are good for joint and deposit welding Which welding process (laser, TIG, MIG/MAG) is used is evaluated and specified individually.

What materials cannot be welded with the laser process?

Die-cast zinc, magnesium, molybdenum, tungsten and brass can’t be laser-welded.

Can we rework (recontour) welded areas?

Our toolmakers can adjust small areas by hand. For further processing of your welded components, we can recommend partner companies nearby.

Is L & A Lasertechnik und Applikationen GmbH certified?

We work according to DIN ISO 9001:2015. This certificate is checked every year by the certification body TÜV SÜD.

What internal transport options are available at our site?

– Hall crane with trolley, capacity 3.25 t

– Electric stacker with triplex mast (1.5 t)

– Manual stacker truck (1.0 t)

– Hand pallet truck (2.5 t)

L&A Lasertechnik und Applikationen GmbH

SPECIALIST IN LASER APPLICATION TECNOLOGY AND SALES AND SERVICE PARTNER OF ALPHA LASER GMBH IN EASTERN GERMANY

Our welding experience in tool and die manufacturing began in 1990. The technology showed promise for that industry, and as a service provider, we have gained many customers all over Germany through its practical implementation.

With sound knowledge and modern machinery, we meet the needs of customers in industries such as: mechanical engineering, medical technology and sensor manufacturing.