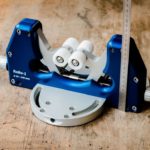

ROLLER BLOCK WELDING DEVICE FOR PIPES

THE ARGUMENTS IN FAVOR OF THE ROBO-1 ROLLER BLOCK:

- Secure mounting and rotation

- Fast, efficient use — suitable for small series

- Reproducible welding (for series)

- Long, thin workpieces are stabilized, no tipping

- Very economical, because setup time is greatly reduced

- Safer work

ROLLER BLOCK: OUR WELDING DEVICE FOR PIPES

No more workarounds! It’s time for our roller block swivel device

With RoBo-1 — our clamping device for round parts — we offer a simple, practical solution for a well-known problem: When round components are longer than average, they often can’t be clamped in one side of the rotation axis. They have to be supported on the second side.

For this we have developed the RoBo-1 roller block. RoBo-1 allows safe positioning of long, rotationally symmetrical components during laser welding. The rollers can be set manually by spindle adjustment.

Even today, many companies use ad hoc workarounds when welding long pipes, such as homemade wooden platforms or horses. At last, RoBo-1 offers a safe, professional solution.

Our roller block is quick to put together and easy to transport. It makes an important contribution to high-quality work by preventing sag and distortion of the components and eliminating vibration during laser welding.

The result is unusually precise weld seams on pipes. Typical applications for the RoBo-1 roller block are pipes, spindles, shafts, rotor shafts for electric motors, pump shafts and camshafts.

TECHNICAL DATA

Magnetic holding sphere

All data and information can be found on this product data sheet.

product sheetL&A Lasertechnik und Applikationen

SPECIALIST IN LASER APPLICATION TECNOLOGY AND SALES AND SERVICE PARTNER OF ALPHA LASER GMBH IN EASTERN GERMANY

Our welding experience in tool and die manufacturing began in 1990. The technology showed promise for that industry, and as a service provider, we have gained many customers all over Germany through its practical implementation.

With sound knowledge and modern machinery, we meet the needs of customers in industries such as: mechanical engineering, medical technology and sensor manufacturing.