L & A Lasertechnik & Applikationen GmbH

Technologien entwickeln – Kompetenzen bündeln

Die L & A Lasertechnik und Applikationen GmbH zählt zu den führenden Spezialisten für Lasertechnik, Laserauftragsschweißen und Edelstahlschweißen im mitteldeutschen Raum.

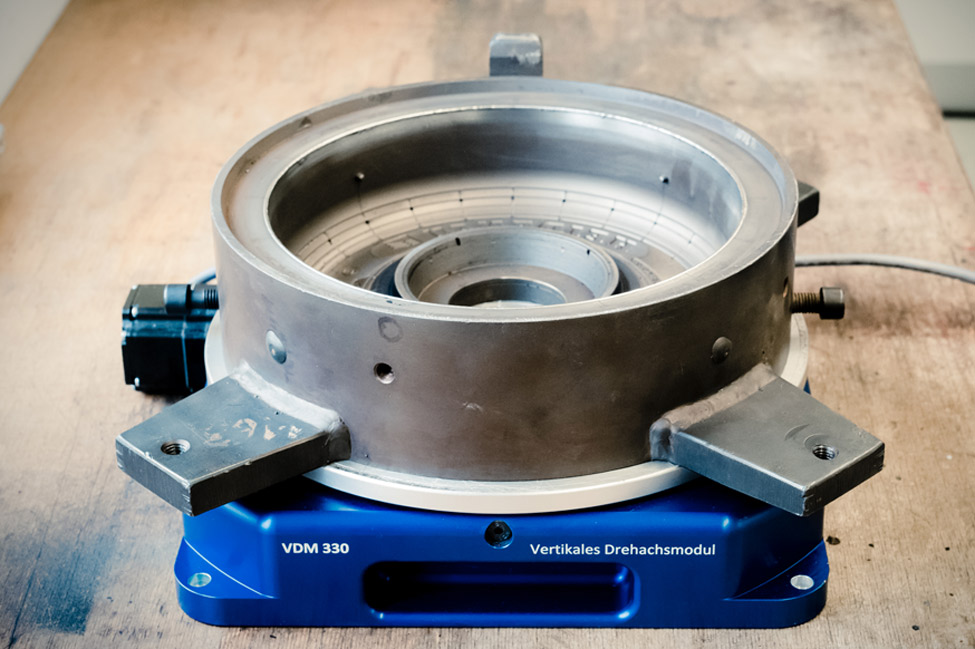

Zum umfangreichen Produkt- und Leistungsportfolio des Unternehmens mit Sitz in Moritzburg bei Dresden zählen auch Lasergravuren bzw. -beschriftungen im 2D- oder 3D-Verfahren.

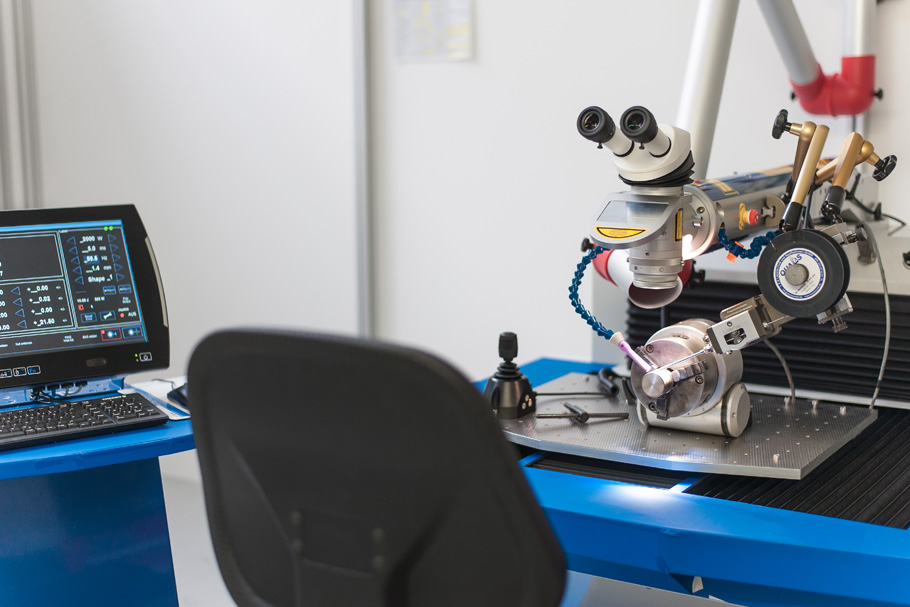

Mit unserem hochmodernen Maschinenpark und einem erfahrenen Team sind wir allen Herausforderungen gewachsen. Das gilt für die Verfahrens- oder Produktentwicklung, die fügetechnische Herstellung von Prototypen und auch für die Serienfertigung.

Unsere Kunden sind in u. a. in Sensorherstellung, Medizintechnik, Maschinen- und Apparatebau sowie Werkzeug- und Formenbau zu Hause.

Als Vertriebs- und Servicepartner der ALPHA LASER GmbH für Ostdeutschland bündeln wir die Kompetenzen eines Lasersystemherstellers und von Laseranwendungstechnologien unter einem Dach. Dieser Erfahrungsschatz fließt auch in die Entwicklung eigener Produkte ein.

Was ist Laserschweißen?

Punktgenaue Schweißnähte, auch an schwer zugänglichen Werkstücken.

Beim Laserschweißen wird die Energie zum Erhitzen der zu verbindenden Bauteile mittels Laser zugeführt. Die Fügetechnologie hat sich in den vergangenen 20 Jahren rasant entwickelt und ist aus der industriellen Fertigung nicht mehr wegzudenken. Sie kommt überall dort zum Einsatz, wo eine hohe Schweißgeschwindigkeit, eine punktgenaue Schweißnaht und minimaler thermischer Verzug gefragt sind.

Zudem eignet sie sich für die Bearbeitung von schwer zugänglichen Bauteilen. Grundsätzlich können alle metallischen Werkstoffe mittels Laserschweißen bearbeitet werden. Im Rahmen des Laserauftragsschweißens bearbeiten wir hauptsächlich Aluminium und Edelstahl.

Die Vorteile des Laserschweißens im Überblick:

- extrem dünne Schweißnähte ohne Nacharbeiten

- durchgängig hohe Qualität

- Erwärmung des Werkstücks örtlich begrenzt, kaum Sekundärwärme

- Verbindung von Metallen mit unterschiedlichen Schmelzpunkt möglich

- Bearbeitung sehr dünner, filigraner Werkstücke

Laserschweißer/in gesucht

Verstärken Sie unser Team.

Wir beschäftigen in Boxdorf (Nähe Dresden) derzeit 15 Mitarbeiter und sind nach ISO 9001:2015 zertifiziert. Unser Kerngeschäft ist das Laserschweißen und das WIG-, MIG/ MAG-Schweißen. Zusätzlich sind wir auf das Laserbeschriften und Lasergravieren spezialisiert. Zur Verstärkung unseres Teams suchen wir zum nächstmöglichen Zeitpunkt eine(n) Laserschweißer/in

L&A Lasertechnik und Applikationen

Spezialist für die Laseranwendungstechnologie sowie Vertriebs- und Servicepartner der ALPHA LASER GmbH für Ostdeutschland

Durch unsere schweißtechnischen Erfahrungen im Werkzeug- und Formenbau seit 1990 war die Anwendung des Laserschweißens in dieser Branche eine erfolgversprechende Technologie, bei deren praktischer Umsetzung wir als Dienstleister viele Kunden bundesweit gewinnen konnten.

Mit fundiertem Wissen und einem modernen Maschinenpark realisieren wir die Aufträge unserer Kunden unter anderem für die Branchen: Maschinenbau, Medizintechnik und Sensorherstellung.

Wir freuen uns auf Ihre Nachricht.

IHRE NACHRICHT

IHR KONTAKT

Wir finden die passende Lösung für Ihre Aufgabenstellung. Bitte kontaktieren Sie uns!

Telefon: +49 351 83 97 96 48

E-Mail: info@laserknechtel.de

Latest Tips & News

Lorem ipsum dolor sit amet, consectetuer. Proin gravida nibh vel velit auctor aliquetenean. Cum sociis Theme natoque penatibus et magnis dis parturient nascetur ridiculus mus